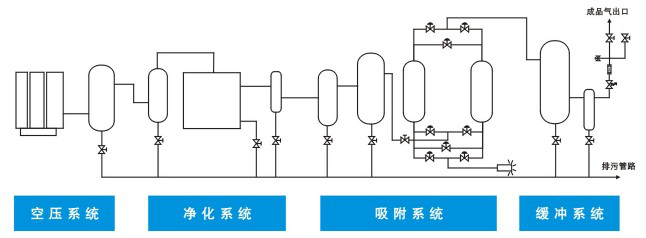

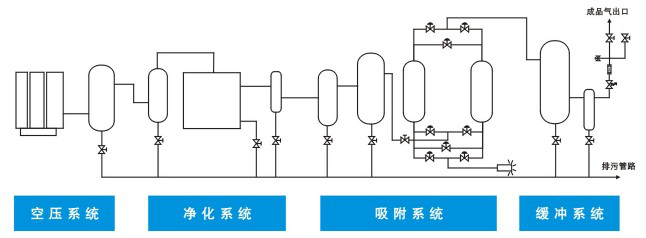

Pressure swing adsorption nitrogen / oxygen production structure process

PSA nitrogen generator is used as pressure swing adsorption principle and high-quality carbon molecular sieve is used as adsorbent to obtain nitrogen directly from compressed air. A complete installation requires an air compressor, refrigerated air dryer, filter, air tank, nitrogen generator and gas buffer tank. We provide complete installation, but each component, and other optional supplies such as booster, high-pressure compressor or gas station can also be purchased separately.

Products Details

Featured Products

-

Container Type Oxygen Generator, container type oxygen generator

-

Cryogenic Air Separation Factory for Reliable Gas Separation Solutions

-

Pressure swing adsorption nitrogen / oxygen production structure process

-

Carbon carrier purification unit

-

Combined Low dew point Compressed air drier

-

Factory Direct Carbon Carrier Purification Unit - Cleanse Air with Ease

-

Refrigerated Compressed Air Dryer

-

Nitrogen Purification Equipment With Hydrogenation

-

Get High-Purity Oxygen for Fresh Water Aquaculture - Direct from Our PSA Oxygen Generator Factory

-

Micro–Heat Compressed Air Dryer

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours