1. The press swing adsorption theory is very stable and reliable. 2. Purity and flow rate can be adjusted in a certain range. 3. Resonable inner structure, keep the balance airflow, alleviate the air high speed impact 4. Unique molecular sieve protective measure, extend the working life of the carbon molecular sieve 5. Easy installation 6. Process automation and easy operation.

1. The press swing adsorption theory is very stable and reliable. 2. Purity and flow rate can be adjusted in a certain range. 3. Resonable inner structure, keep the balance airflow, alleviate the air high speed impact 4. Unique molecular sieve protective measure, extend the working life of the carbon molecular sieve 5. Easy installation 6. Process automation and easy operation. PSA Nitrogen Generator Skid full sets supplier

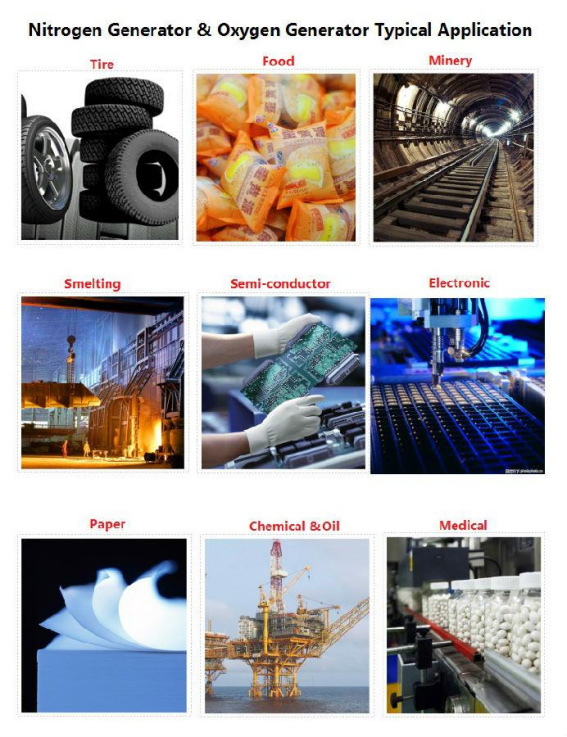

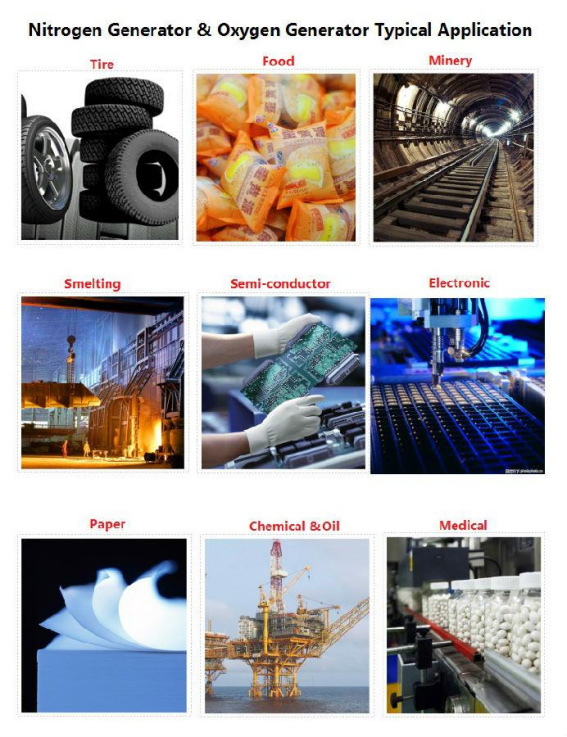

PSA Nitrogen generator is used as the principle of pressure swing adsorption, The nitrogen is obtained from compressed air directly by using high quality carbon molecular sieve as adsorbent. A full installation requires air compressor, refrigerated air dryer, filters, air tank, nitrogen generator and gas buffer tank. We supply full installations but each component, and other optional supply like boosters, high pressure compressors or filling stations can also be bought separately.

Products Details

1. The press swing adsorption theory is very stable and reliable. 2. Purity and flow rate can be adjusted in a certain range. 3. Resonable inner structure, keep the balance airflow, alleviate the air high speed impact 4. Unique molecular sieve protective measure, extend the working life of the carbon molecular sieve 5. Easy installation 6. Process automation and easy operation.

1. The press swing adsorption theory is very stable and reliable. 2. Purity and flow rate can be adjusted in a certain range. 3. Resonable inner structure, keep the balance airflow, alleviate the air high speed impact 4. Unique molecular sieve protective measure, extend the working life of the carbon molecular sieve 5. Easy installation 6. Process automation and easy operation. Featured Products

-

Get High-Purity Oxygen for Fresh Water Aquaculture - Direct from Our PSA Oxygen Generator Factory

-

Carbon carrier purification unit

-

Nitrogen Purification Equipment With Hydrogenation

-

Quality PSA Nitrogen Generator Skid Sets: Directly from Factory Supplier

-

Degreasing agent, high efficiency degreasing agent, new degreasing type

-

PSA oxygen generator fresh water aquaculture high purity oxygen generator

-

Air-cooled Dryer, water-cooled Dryer, Dryer

-

Principle of PSA nitrogen production

-

PSA oxygen generator - oxygen generating equipment - high purity oxygen generator

-

Factory Direct: PSA Nitrogen Generator Skid Full Sets Supplier

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours